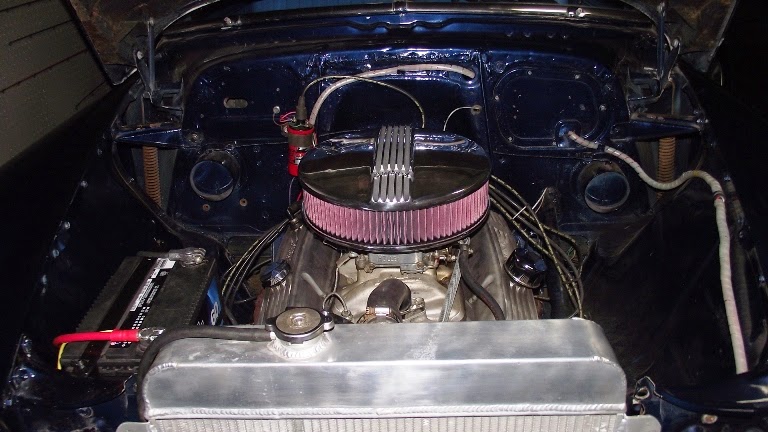

Pretty basic but it's all I have right now LOL

Hood closes fine and no clearance issues.

Some unexpected things are in the works, I'll fill you in later.

Friday, February 27, 2015

Hood Support & Glue Sticks for Men

I got the hood support finished up. I am debating on glossy paint now or wait until I do the underside of the hood. For now it has Rustoleum Rust Reformer to keep it safe.

Here are some original pictures I posted earlier....

Here is the final outcome...

Now to see if it fits! ;)

Here are some original pictures I posted earlier....

Here is the final outcome...

Now to see if it fits! ;)

Wednesday, February 25, 2015

Transmission Cooler

I got the transmission cooler installed. I had several places in mind to mount it but none had the room needed :( I ended up putting it on the inner fender wall, right in front of the air vent that would normally route air to the inside but the tubes are missing from the car. Once I got it all together I had a huge leak. I had noticed fluid on one of the fittings on the trans but I had hope it was just not tight enough. Not the case. The fitting had been stripped at some point so I made a trip to the parts store and picked up a new one. It's good to go now.

Fits just under the battery tray....

Two trans cooler lines go to hard line and from there about a foot to the trans. I ran the car for about 15 minutes and I did not see any leaks. I also noted it took the car a while to start registering a temperature on the gauge. I will need to install the thermostat at some point. I already have it but I want to replace the hoses at the same time and I do not have those yet.

I started welding on the hood support brace today as well. I do not have pictures yet. I should have some for tomorrows progress.

Fits just under the battery tray....

Two trans cooler lines go to hard line and from there about a foot to the trans. I ran the car for about 15 minutes and I did not see any leaks. I also noted it took the car a while to start registering a temperature on the gauge. I will need to install the thermostat at some point. I already have it but I want to replace the hoses at the same time and I do not have those yet.

I started welding on the hood support brace today as well. I do not have pictures yet. I should have some for tomorrows progress.

Monday, February 23, 2015

Polish and Hood Support

I finished polishing the valve covers. They came out pretty good. Definitely much better than what I started with. I did not post here right away since I loaded up facebook with the pictures and most who watch this, see that. Here are the pics ...

Note in the picture above the fuel line and throttle spring are all over the place. I cleaned them up a bit ....

Today I decided to go ahead and section the hood support so I can put it back on and be able to close the hood with the radiator in it's new position. I could have just notched it and been done with it but I wan a finished look. Here is the start. I also wire wheeled it to remove the rust and old paint.

After...

Basically I am just moving the outer edge back about 2 inches. That should allow the hood to close and miss the radiator as well as keep the support needed for the hood. This will also leave all the original mounting locations in tack.

Note in the picture above the fuel line and throttle spring are all over the place. I cleaned them up a bit ....

Today I decided to go ahead and section the hood support so I can put it back on and be able to close the hood with the radiator in it's new position. I could have just notched it and been done with it but I wan a finished look. Here is the start. I also wire wheeled it to remove the rust and old paint.

|

| BEFORE |

Basically I am just moving the outer edge back about 2 inches. That should allow the hood to close and miss the radiator as well as keep the support needed for the hood. This will also leave all the original mounting locations in tack.

Friday, February 20, 2015

Radiator Woes & Some Elbow Grease

I really have not done much to the car since my last post. It has been abnormally cold here in the South. I did order new bungs for the radiator and I called the radiator guy near my house to see if he could fix it.

The parts came in but they look to be too big. Well actually they are too big. I ordered half inch thread size and these measure 3/4 inside diameter. So, either I am doing something wrong or they sent the wrong part. The part numbers for Be Cool as well as Summit say half inch. I wrote Summit and email inquiring. We will see.

Also the radiator shop said they could not fix it. Hmmm I am not sure if he just can't weld aluminum or if it can't be fixed?? I guess I should have asked but I am pretty sure it can be fixed. It will be a matter of finding someone who can. Heck I would attempt it if I had the aluminum spool and gas for my welder.

For now the compromise or fix will be an external cooler. I found one I like and I think it will work just fine. It should be here next week, weather permitting. I went with a Radiator Express 15 inch Dual Pass....

In the meantime I have been working on the valve covers. They are pretty dingy so I removed them and started the process. First I sand with 150 grit, then 400, 600, and 1500. Then I hit it with 00 steel wool. Once it looks semi smooth I use Mothers aluminum polish applied with my Dremel. They wont be like new or scratch free but will look a ton better than they did. One day I will break down and get something that will mechanically polish and rework them.

Here are some before shots ....

This was taken after I washed it up .....

This is after sanding with polish applied and still on the cover. I ran out of time so I will knock that off tomorrow and see how it looks.

The parts came in but they look to be too big. Well actually they are too big. I ordered half inch thread size and these measure 3/4 inside diameter. So, either I am doing something wrong or they sent the wrong part. The part numbers for Be Cool as well as Summit say half inch. I wrote Summit and email inquiring. We will see.

Also the radiator shop said they could not fix it. Hmmm I am not sure if he just can't weld aluminum or if it can't be fixed?? I guess I should have asked but I am pretty sure it can be fixed. It will be a matter of finding someone who can. Heck I would attempt it if I had the aluminum spool and gas for my welder.

For now the compromise or fix will be an external cooler. I found one I like and I think it will work just fine. It should be here next week, weather permitting. I went with a Radiator Express 15 inch Dual Pass....

In the meantime I have been working on the valve covers. They are pretty dingy so I removed them and started the process. First I sand with 150 grit, then 400, 600, and 1500. Then I hit it with 00 steel wool. Once it looks semi smooth I use Mothers aluminum polish applied with my Dremel. They wont be like new or scratch free but will look a ton better than they did. One day I will break down and get something that will mechanically polish and rework them.

Here are some before shots ....

This was taken after I washed it up .....

This is after sanding with polish applied and still on the cover. I ran out of time so I will knock that off tomorrow and see how it looks.

Sunday, February 15, 2015

Wiring The Fuel Pump

Today was the day to fix the electric fuel pump wiring.

For those who have not been following along, the pump was wired without any safety measures. In other words the engine could stop and the pump would continue pumping gas to the carburetor. If you turn the switch on it starts to pump. To solve this problem, the common method is to install an oil pressure switch. This switch will activate the pump once the engine oil pressure rises as you turn over the engine to start the car. If your engine stalls and the ignition is on it will not pump gas.

Also the pump was wired without a relay. The basic purpose of any electric relay is to use a lower amp circuit to activate the relay (like closing a switch) to activate a high amp circuit. This isolates the control circuit from the power supply circuit. Using the relay allows your fuel pump to run more efficiently with less stress on the electrical circuit as well as the pump.

Each part came with instructions but neither included the use of the other. I found a diagram online that shows how it's done. I had to tweak it a little for my application and will explain that later.

Here is the site and diagrams I referenced LINK LINK LINK on how to install an electric fuel pump. (link will open in a new window)

Here is the diagram...

NOTE: Be sure and disconnect your battery before you start your installation!

Where the oil pressure switch calls for hook ups to the ignition switch and starter, I have the push button ignition set up in my car, so I just went to those two wires. Basically it's the same thing... ignition and starter. If it were drawn on this diagram it would show the push button circuit rather than the ignition switch.

The large Power wire to the starter where the battery connects. This line should have a circuit breaker inline as a safety precaution. The Summit kit I purchased came with one.

I could not mount my pressure switch right on the port at the back of the intake because the "T" connection I would need (so I could also keep my oil pressure gauge) was shaped in a way it would not clear the intake to screw in. I could not locate another port to use so I installed the "T" and pressure switch up on the firewall. I ran the oil tube up to the "T" on the firewall. I have the pressure switch on the inside of the car poking through enough to screw on the "T". Once I had that I just screwed on my oil pressure gauge line. I think I will probably change this out once I locate another access port on the block.

I moved the fuse box up a bit and corrected it's orientation. Once I had that where I wanted it I installed the relay next to it.

I did not hear the pump when I turned the switch on without starting the car. I started the car up and the switch worked as it should.

Now I need to install kick panels and reroute some wires to the brake switch that run straight down from the steering column.

I put my hood support panel bolts and screws in vinegar to remove the rust. I won't do anything with the support until I have a plan for the radiator fix. I found a radiator shop near my house so I will call tomorrow and see if they can fix the stripped out transmission cooler bung. If they can't I may just order a stand alone cooler and forget about it. That would work fine here in the south.

For those who have not been following along, the pump was wired without any safety measures. In other words the engine could stop and the pump would continue pumping gas to the carburetor. If you turn the switch on it starts to pump. To solve this problem, the common method is to install an oil pressure switch. This switch will activate the pump once the engine oil pressure rises as you turn over the engine to start the car. If your engine stalls and the ignition is on it will not pump gas.

Also the pump was wired without a relay. The basic purpose of any electric relay is to use a lower amp circuit to activate the relay (like closing a switch) to activate a high amp circuit. This isolates the control circuit from the power supply circuit. Using the relay allows your fuel pump to run more efficiently with less stress on the electrical circuit as well as the pump.

Each part came with instructions but neither included the use of the other. I found a diagram online that shows how it's done. I had to tweak it a little for my application and will explain that later.

Here is the site and diagrams I referenced LINK LINK LINK on how to install an electric fuel pump. (link will open in a new window)

Here is the diagram...

NOTE: Be sure and disconnect your battery before you start your installation!

Where the oil pressure switch calls for hook ups to the ignition switch and starter, I have the push button ignition set up in my car, so I just went to those two wires. Basically it's the same thing... ignition and starter. If it were drawn on this diagram it would show the push button circuit rather than the ignition switch.

The large Power wire to the starter where the battery connects. This line should have a circuit breaker inline as a safety precaution. The Summit kit I purchased came with one.

I could not mount my pressure switch right on the port at the back of the intake because the "T" connection I would need (so I could also keep my oil pressure gauge) was shaped in a way it would not clear the intake to screw in. I could not locate another port to use so I installed the "T" and pressure switch up on the firewall. I ran the oil tube up to the "T" on the firewall. I have the pressure switch on the inside of the car poking through enough to screw on the "T". Once I had that I just screwed on my oil pressure gauge line. I think I will probably change this out once I locate another access port on the block.

|

| "T" Connection for pressure switch. |

|

| Oil Pressure switch |

I moved the fuse box up a bit and corrected it's orientation. Once I had that where I wanted it I installed the relay next to it.

|

| The relay you see on the fuse block is for the horn. The one I installed is the black square to the right of the fuse block. |

|

| Tidy |

I did not hear the pump when I turned the switch on without starting the car. I started the car up and the switch worked as it should.

Now I need to install kick panels and reroute some wires to the brake switch that run straight down from the steering column.

I put my hood support panel bolts and screws in vinegar to remove the rust. I won't do anything with the support until I have a plan for the radiator fix. I found a radiator shop near my house so I will call tomorrow and see if they can fix the stripped out transmission cooler bung. If they can't I may just order a stand alone cooler and forget about it. That would work fine here in the south.

Friday, February 13, 2015

The Good, Bad, and the Ugly!

I got rid of a little bit of ugly by installing this monster air filter housing! It is an Edelbrock Classic Series to match the valve covers. Of course I will need to polish the valve covers so they don't look so dingy.

I removed the oil filler cap that , to me, looked like a radiator cap from the valve cover and put in a push in type. It looks much better.

I also routed the temperature sender to hide it better.Before it was going across the front and back to the original gas peddle hole. I ran it down the opposite side (passenger) and went in with the speedometer cable at the hole where the original column shifter was. If I decide to leave them there I will put in a grommet.

I went ahead and replaced the starter and all of the ground straps as well as the positive battery cable. The old cable was good but black. I needed it to be red. LOL It also allowed me to hook the alternator wire up the right way.

The ground strap kit had one 11 inch fat braided cable and 3 smaller ones. I put the big one at the front from the block to the frame. I put a small one on the passenger side at the frame to the firewall and on that same side from a valve cover bolt to the firewall. I will probably use the last one on the other side , frame to fender well. By putting these flat cables in I got rid of the ugly the red cables where causing. If you did not see them in older pictures, a previous owner installed red battery cables as grounds. They were way too long and looked like crap. They won't be missed.

The starter was an easy install and did not require any shims. I was concerned because I could not get to the gear to bring it out and check clearance. The transmission lines are in the way. I actually had to install it by dropping it in from the top.

The car turns over easily now and starts right up. So far so good!

I also took the electric fan off of the front of the radiator. It was like someone put it on as an afterthought. It pulled air through the radiator and would have been useless at highway speeds with the air coming through the grill fighting it. Also they had tilted the radiator forward at the top so it would clear the plate the hod latches to.

I moved the radiator back as close as I could and then installed a Flex Fan. I had to use a one inch spacer to move the blades away from my alternator. This put the fan at about 3/4 to 1 inch from the radiator!

The only down fall in doing this so far is the hood would not close. The top of the radiator hit on the support bracket running across the front underside of the hood. I marked it and removed it to make sure it would close without it. It does. So all I will have to do is cut out a section of the brace and put it back in.. Sweet. I intend to section the bracket so it doesn't look like it was just cut up. We will see how that goes.

My radiator hoses actually reached the new position but I will be replacing them. They are old and soft as well as a bit short. I also want to firm up the mounts for the radiator. I put it back like it was with bolts but it really needs more support. I did manage to lower it about an inch which gave me a little more room under the hood.

Now the bad...

One of the transmission lines was stripped at the bottom of the radiator. I feel like there was an issue before I ever touched it. I hardly tightened the lines at all and they would just not firm up. Of course when I started the car fluid spewed all over. At least I got to make sure the fan was going to clear everything. So I will either have to find a radiator repair shop or replace the whole thing. I may go the later route. This radiator has some damage to the cooling fins and I would not mind finding one with a side fill to give more clearance. I wont cut the hood brace until I figure out the radiator deal. For now the car wont be going anywhere. :o(

In the meantime I also got the stuff to straighten out my fuel pump. I picked up a relay as well as an oil pressure switch so it will shut down when the engine stops. This is a must for safety. If you had an accident and the gas kept pumping it could end in disaster! I had to get a T fitting too so I could still have my oil pressure gauge connected. I hope everything fits!. I will probably knock this out tomorrow.

I removed the oil filler cap that , to me, looked like a radiator cap from the valve cover and put in a push in type. It looks much better.

I also routed the temperature sender to hide it better.Before it was going across the front and back to the original gas peddle hole. I ran it down the opposite side (passenger) and went in with the speedometer cable at the hole where the original column shifter was. If I decide to leave them there I will put in a grommet.

I went ahead and replaced the starter and all of the ground straps as well as the positive battery cable. The old cable was good but black. I needed it to be red. LOL It also allowed me to hook the alternator wire up the right way.

The ground strap kit had one 11 inch fat braided cable and 3 smaller ones. I put the big one at the front from the block to the frame. I put a small one on the passenger side at the frame to the firewall and on that same side from a valve cover bolt to the firewall. I will probably use the last one on the other side , frame to fender well. By putting these flat cables in I got rid of the ugly the red cables where causing. If you did not see them in older pictures, a previous owner installed red battery cables as grounds. They were way too long and looked like crap. They won't be missed.

The starter was an easy install and did not require any shims. I was concerned because I could not get to the gear to bring it out and check clearance. The transmission lines are in the way. I actually had to install it by dropping it in from the top.

The car turns over easily now and starts right up. So far so good!

I also took the electric fan off of the front of the radiator. It was like someone put it on as an afterthought. It pulled air through the radiator and would have been useless at highway speeds with the air coming through the grill fighting it. Also they had tilted the radiator forward at the top so it would clear the plate the hod latches to.

I moved the radiator back as close as I could and then installed a Flex Fan. I had to use a one inch spacer to move the blades away from my alternator. This put the fan at about 3/4 to 1 inch from the radiator!

The only down fall in doing this so far is the hood would not close. The top of the radiator hit on the support bracket running across the front underside of the hood. I marked it and removed it to make sure it would close without it. It does. So all I will have to do is cut out a section of the brace and put it back in.. Sweet. I intend to section the bracket so it doesn't look like it was just cut up. We will see how that goes.

My radiator hoses actually reached the new position but I will be replacing them. They are old and soft as well as a bit short. I also want to firm up the mounts for the radiator. I put it back like it was with bolts but it really needs more support. I did manage to lower it about an inch which gave me a little more room under the hood.

Now the bad...

One of the transmission lines was stripped at the bottom of the radiator. I feel like there was an issue before I ever touched it. I hardly tightened the lines at all and they would just not firm up. Of course when I started the car fluid spewed all over. At least I got to make sure the fan was going to clear everything. So I will either have to find a radiator repair shop or replace the whole thing. I may go the later route. This radiator has some damage to the cooling fins and I would not mind finding one with a side fill to give more clearance. I wont cut the hood brace until I figure out the radiator deal. For now the car wont be going anywhere. :o(

In the meantime I also got the stuff to straighten out my fuel pump. I picked up a relay as well as an oil pressure switch so it will shut down when the engine stops. This is a must for safety. If you had an accident and the gas kept pumping it could end in disaster! I had to get a T fitting too so I could still have my oil pressure gauge connected. I hope everything fits!. I will probably knock this out tomorrow.

Subscribe to:

Posts (Atom)